The metal you choose, as well as the properties of the metal, will play a critical role in determining whether or not the final part will be successful in its construction, depending on the part or product that is being CNC machined. For example, the ability to withstand extreme temperatures as well as the ability to resist bending or breaking when subjected to pressure are just a few of the requirements that must be met.

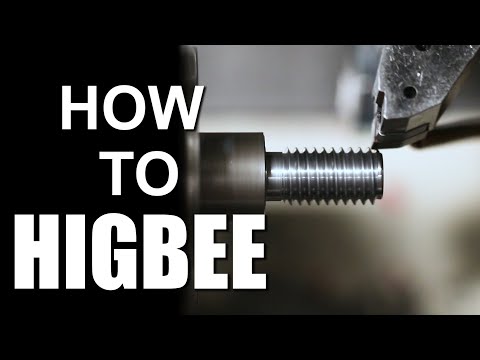

Is it possible for a CNC machine to cut through metal with its cutting head when it is in operation?

CNC machines are available in a variety of configurations to meet your specific needs and requirements. Here are a few of the most widely used CNC machining techniques: CNC milling, CNC turning, and CNC drilling. the use of numerical control in machining

CNC milling (Computer Numerical Control) is a type of milling in which the cutting process is controlled by a computer rather than by a human operator, as opposed to conventional milling.

CNC machines or computer numerically controlled machines (CNC machines) are machine tools that use computer numerical control (CNC) to control the cutting process. CNC machines are also known as computer numerically controlled machines (CNC machines).

To make your selection from, there is a large variety of metals in various shapes and sizes that are suitable for available. In the remainder of today's blog post, we'll discuss the various types of metals that are commonly used in titanium cnc machining applications, as well as the characteristics of each metal. These recommendations, in addition to being applicable to CNC turning and multi-axis manufacturing, can be applied to a wide range of other manufacturing operations.

Metals are being machined with the help of computer-controlled technology.

Due to its exceptional strength and resilience, titanium is a popular choice for aerospace applications because of its high strength-to-weight ratio while remaining lightweight. Welding takes only a short period of time and requires little effort due to the high degree of workability of the material. While titanium responds well to anodizing because of the clean finish and protection it provides, titanium does not respond well to polishing for the same reasons. In aerospace and defense, aluminum, a lightweight and strong metal with excellent corrosion resistance and high-temperature resistance, is used as a structural component. It is also used in a variety of industries, including the aerospace and defense industries. Due to its high strength and corrosion resistance, titanium is widely used in aerospace and defense components, as well as in medical devices and other military applications. The titanium alloy Ti6Al4V (also known as TC4 and Grade 5) is a popular grade of titanium alloy that is used in a wide range of applications. It is also known as TC4 and Grade 5. Ti6Al4V is also referred to as TC4 and Grade 5 in some circles.

Stainless steel, specifically austenitic stainless steel, is the subject of today's lecture because it is the most commonly encountered type of stainless steel in the manufacturing industry. Machined parts are most frequently encountered in Precision CNC Machining processes, and the following are the three grades of CNC machining most frequently encountered in CNC machining processes:

This is largely due to the fact that stainless steel is extremely corrosion-resistant and has a high melting point, which makes it the most widely used steel in the world and the most widely used steel in the world. When compared to other stainless steel alloys on the market, this stainless steel alloy has superior welding and formability characteristics, making it an excellent choice for screws, machinery parts, car headers, and food handling equipment, among other applications.

Stainless steel 316 is an excellent choice for marine-grade applications due to its high strength and ease of welding capabilities. Because of its strength and ease of welding, it is also an excellent choice for structural applications such as building foundations. Beyond that, steel is used in the production of medical implants and surgical instruments, among other things. There are a variety of other industries that make use of this material, including the aerospace industry, among others.

Aluminum 7075 is considered to be one of the highest-grade metals available, and it is renowned for its exceptional strength and durability. It is used in a variety of industries including the aerospace and defense industries, among others. In part due to its superior strength to weight performance in comparison to other materials, Al7075 is particularly well suited for CNC-machined parts that require long-term durability, such as frame components in the automobile and aerospace industries. As a result, it has risen to become one of the most widely used materials in the aerospace industry, particularly for structural components that are subjected to extreme levels of stress.

When compared to aluminum, magnesium AZ31 has a higher strength-to-weight ratio and can be up to 35% lighter while retaining the same strength and stiffness characteristics, allowing for more efficient manufacturing. As you might expect, the increased complexity results in a higher price point on the pricing scale, which raises the overall cost of the product.

Brass is a highly adaptable metal that can be used in a variety of situations and applications due to its versatility.

This particular steel grade exhibits high levels of strength while also being more cost-effective than stainless steel, which is due to the fact that it is less expensive than stainless steel. In addition to resilient mechanical parts such as gears, nuts, and other fasteners, a material that is similar to stainless steel 303 is frequently used in other applications. It is also a superior steel for applications requiring higher strength or hardness, such as bearings.

A number of steel alloys are contained within it, and they are used in the production of D2 Steel and other steel-based products among other things.

Buscar

entradas populares

Categorías

- Automóviles y Vehículos

- Negocios y Oportunidades

- Economía y Comercio

- Educación

- Entretenimiento

- Cine y Animación

- Juego de azar

- Historia y Datos

- Estilos de vida

- Servicios

- Noticias y Política

- Pueblos y Naciones

- Animales y mascotas

- Lugares y Regiones

- Ciencia y Tecnología

- Deporte

- Viajes y Eventos

- Contactos

- Esoterismo

- Informatica

- Transportes

- Turismo

- Salud y Belleza

- Construcción

- Otro