As an engineer, you're constantly on the lookout for ways to mitigate challenges in the manufacturing industry – a world that is, by its very nature, difficult to navigate.Because of the implementation of newer technologies such as additive manufacturing (3D printing) processes, you now have the ability to overcome more obstacles than you ever have before.

When compared to the length of time that manufacturing has been around, these 3d printing technologies are still in their early stages.As a result, not everyone is aware of the advantages of using them or the problems that can be resolved as a result of doing so.In the meantime, let's take a quick look at the five ways that 3d printing is making engineers' lives easier, shall we?

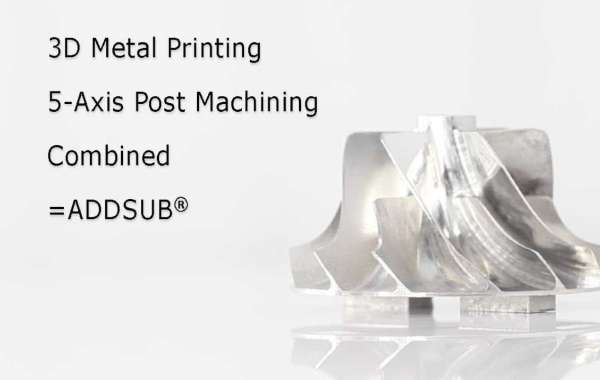

Producing high-quality products takes time and patience.Progress in the field of Metal 3D Printing, on the other hand, is aimed at reducing projected lead times and, as a result, the amount of time it takes to bring a product to market.Some manufacturers are able to reduce their lead times by up to 70% in their current state of affairs, and those percentages are expected to grow - on average - with each passing year.

In today's economy, manufacturers are constantly looking for ways to save money, and incorporating various methods of 3D printing into their manufacturing processes can help them achieve this goal.According to reports, certain Plastic 3D Printing technologies, such as PolyJet, have enabled some businesses to reduce their costs by as much as 95%. PolyJet is one such technology.Even though large-scale cost savings of this magnitude are uncommon today, technological and material advancements may make figures like these more common in the future.

When it comes to traditional manufacturing, mistakes made during the prototyping and redesigning process can cost a company a significant amount of time and money.When comparing Online 3D Printing to traditional manufacturing processes, it is significantly more feasible and significantly less expensive to make changes on the fly with the former.When it comes to 3D printing, there is a level of convenience that is unmatched by older methods of production and fabrication.

In addition to the level of complexity that can be achieved when fabricating parts in a controlled environment, one of the most enticing aspects of additive manufacturing is the cost effectiveness of the process.It is not necessary to take into consideration issues such as draft angles and tool access when using additive manufacturing because many of the constraints associated with traditional manufacturing are not present.With the increased flexibility in their designs, engineers are able to create designs that were previously deemed unworkable due to their complexity.

Sustainable manufacturing has been a source of debate in the manufacturing industry for many years, and with the increase in consumer spending, materials are being consumed at a faster rate than at any time in history.Furthermore, if advancements in {anchor} technologies continue in this vein, they will eventually lead to a point where manufacturing is universally recognized as being economically viable over the long term.Reduced environmental impact of manufacturing is an enormous challenge that must be met in the meantime, and 3D printing is unquestionably a step in the right direction.

It is mandatory for many industries for companies to maintain a stock of the parts and products that they require or that they sell.This comes at a significant financial expense.As 3D printing becomes more widely used in the manufacturing industry, it has the potential to lower costs by decreasing the amount of storage space required.The use of 3D printing makes it possible to manufacture goods in the same location where they will be sold, which is advantageous.The absence of overproduction and the avoidance of increased storage costs are the results of this arrangement